“Where Every Second Counts, and Every Sensor Matters”

Oil and gas operations are inherently hazardous. Workers contend daily with combustible vapors, toxic gases, extreme temperatures, high-pressure systems, and heavy machinery, often in remote locations that are challenging to monitor manually. Because traditional safety systems and manual logs are often too slow to respond to fast-emerging threats, IoT safety solutions for oil and gas transform safety from a reactive process into a proactive, continuous digital shield.

Real-time monitoring and intelligent analytics ensure that hazards are detected and mitigated before they escalate into catastrophic events.In environments where a single missed signal can have disastrous consequences, IoT ensures that no second and no sensor goes unnoticed.

Key Takeaway: IoT functions as a continuous, always-on safety network protecting workers, equipment, and the environment.

Inside the Digital Safety Net: How IoT Systems Work in Hazardous Environments

IoT systems in industrial settings rely on interconnected layers of sensors, analytics, and automated responses. Key components include:

Key Components of IoT for Safety:

- Wearables: Smart helmets, badges, and wristbands that monitor vitals, fatigue, and detect falls.

- Environmental Sensors: Gas detectors for methane, H₂S, CO, VOCs; air quality, pressure, temperature, and humidity monitoring.

- Asset Monitoring Sensors: Vibration, thermal, pressure, corrosion, and leak detection sensors enabling predictive maintenance.

- Real-Time Location Systems (RTLS): Track individuals in confined spaces, offshore platforms, and large refineries.

- Connectivity Infrastructure: Mesh networks, LPWAN, Wi-Fi, satellite links, and edge computing for seamless data flow.

- Cloud & Analytics: Dashboards, anomaly detection, and automated safety triggers.

- Emergency Systems: Automatic alarms, shutdowns, ventilation control, and evacuation alerts.

Key Takeaway: IoT operates as a continuous loop: Sense → Transmit → Analyze → Alert → Act.

Why IoT Is Essential in Oil & Gas Hazard Monitoring?

The oil and gas sector faces rapidly evolving risks that change by the second, making human oversight alone insufficient for managing complex, remote sites around the clock. IoT safety solutions for oil and gas have become essential in this environment, enabling real-time hazard detection to prevent explosions, leaks, and equipment failures, while also supporting continuous monitoring of worker health factors such as heat stress, fatigue, and toxic exposure. By leveraging predictive analytics, organizations can minimize downtime, avoid costly failures, and optimize maintenance operations. IoT systems further support compliance with stringent environmental, health, and safety regulations. In an industry where milliseconds matter, IoT provides the visibility and speed that no human observer can match.

Key Takeaway: IoT transforms hazard management from a reactive firefighting exercise into a proactive, predictive operation.

Core IoT Applications for Hazard Monitoring in Oil & Gas

Implementing comprehensive IoT safety solutions for oil and gas facilitates continuous gas and environmental hazard detection, allowing operators to identify toxic substances such as methane and hydrogen sulfide while monitoring for pressure or temperature abnormalities. These systems can automatically trigger alarms, activate ventilation, or initiate shutdown procedures when dangerous conditions arise.

Worker safety is further enhanced through real-time location monitoring and wearable technologies that detect heart rate spikes, heat stress, exhaustion, and other physiological risks. Smart helmets can identify falls, impacts, or immobility, while RTLS systems support rapid rescue efforts and prevent unauthorized access to hazardous zones. Lone-worker monitoring adds an additional layer of protection by alerting supervisors instantly when an employee is in distress.

Predictive equipment monitoring and integrity management leverage vibration sensors to detect early signs of mechanical failure, corrosion and leak detection systems to maintain pipeline integrity, and thermal sensors to prevent overheating and fire hazards. These insights enable predictive maintenance that reduces unplanned downtime and minimizes the likelihood of catastrophic failures. Integrated IoT safety platforms further unify these capabilities by providing real-time visibility across entire facilities. Automated alerts notify supervisors, control rooms, and emergency teams, while triggered protocols can manage shutdowns, ventilation, and evacuation procedures. Comprehensive data logs generated by these systems support regulatory compliance, audits, and detailed incident investigations.

Key Takeaway: The strongest advantage of IoT lies in system-wide, automated safety response.

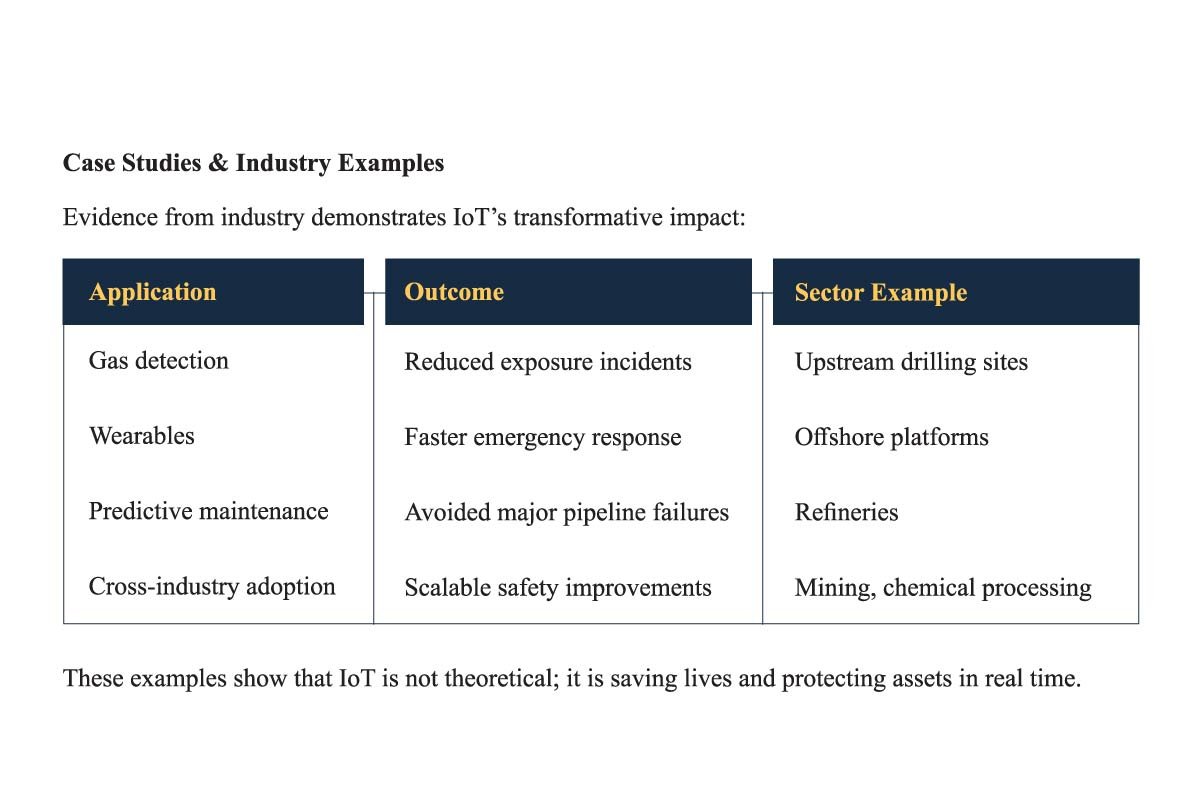

Case Studies & Industry Examples

Evidence from industry demonstrates IoT’s transformative impact:

| Application | Outcome | Sector Example |

| Gas detection | Reduced exposure incidents | Upstream drilling sites |

| Wearables | Faster emergency response | Offshore platforms |

| Predictive maintenance | Avoided major pipeline failures | Refineries |

| Cross-industry adoption | Scalable safety improvements | Mining, chemical processing |

These examples show that IoT is not theoretical; it is saving lives and protecting assets in real time.

The Future of IoT for Hazardous Environment Safety

Emerging trends indicate a future in which IoT safety solutions for oil and gas become even more intelligent, autonomous, and deeply integrated into operations. AI-driven predictive hazard modeling will enable earlier identification of risks, while edge AI will support autonomous response systems capable of taking immediate action without human intervention. Entire facilities will increasingly be represented through digital twins, allowing operators to simulate scenarios, test responses, and optimize performance.

Robotics and drones will play a larger role in conducting high-risk inspections, reducing exposure for frontline workers. Next-generation smart PPE will incorporate augmented reality overlays, advanced fatigue tracking, and enhanced biometric sensing. At the industry level, standardized IoT safety frameworks are expected to emerge, alongside the integration of ESG metrics directly into safety and environmental monitoring systems. Together, these advancements will create safer, more efficient, and more accountable operations across the sector.

Tomorrow’s safety systems will detect hazards, anticipate them, and even neutralize risks before they occur.

Key Takeaway: The next generation of IoT will be intelligent, autonomous, and self-adaptive.

Challenges & Risks in Deploying IoT for Hazard Monitoring

Despite its advantages, IoT adoption carries challenges:

- Data Overload: Excessive alerts without filtering can overwhelm operators.

- Sensor Degradation: Corrosion, dust, vibration, and heat can reduce sensor accuracy.

- Connectivity Limitations: Remote wells and offshore rigs may lack reliable networks.

- Cybersecurity Threats: Each IoT endpoint represents a potential vulnerability.

- High Upfront Investment: Hardware, integration, and training costs can be significant.

- Worker Resistance: Concerns over monitoring and privacy must be addressed.

- Legacy Integration: IoT must complement existing SCADA and safety systems.

Key Takeaway: The benefits of IoT rely on robust design, reliable hardware, and secure integration.

A Strategic Roadmap for IoT Adoption in Hazardous Facilities

A successful implementation of IoT safety solutions for oil and gas combines technology with operational culture. Key steps include:

- Conduct risk and workflow assessments.

- Start with pilot deployments in high-risk zones.

- Ensure strong connectivity and edge computing infrastructure.

- Implement robust cybersecurity measures.

- Train and onboard workers early.

- Define KPIs: fewer incidents, faster response times, reduced downtime.

- Scale deployment site by site.

- Use long-term analytics to inform predictive safety strategies.

Key Takeaway: IoT adoption is as much cultural and operational as it is technical.

Conclusion: The Connected Hazard Zone of the Future

IoT safety solutions for oil and gas empower facilities to detect, analyze, and respond to hazards in real time. Traditional systems alone cannot achieve this level of visibility or speed. By integrating wearables, environmental sensors, predictive analytics, and automated emergency protocols, IoT reduces risk to workers, protects the environment, minimizes downtime, and strengthens regulatory compliance.

In the hazardous landscapes of oil and gas operations, the connected facility is not just safer, it is smarter, faster, and more resilient. Companies that embrace IoT today will define the standard for safety and operational excellence tomorrow.