In the grand tapestry of construction and manufacturing, there exists a pivotal craft that melds artistry with engineering precision – steel fabrication. Beyond the raw strength of steel lies a meticulous process, where skilled artisans transform malleable metal into the skeletal framework of our modern world.

Understanding Steel Fabrication

The fabrication of steel is the process of transforming raw steel into predefined shapes and structures through cutting, bending, and assembling. This intricate craft involves skilled professionals who meticulously craft everything from small components to large structures. The journey of steel from its raw form to a finished product involves several crucial steps.

1. Design and Planning

The process begins with meticulous design and planning. Engineers and architects collaborate to create detailed blueprints that outline the specifications and requirements of the final product. Advanced computer-aided design (CAD) software ensures precision in every detail, allowing for accurate representation and modification before actual fabrication begins.

2. Material Selection

Steel fabrication relies on a variety of steel types, each with its unique properties and applications. Commonly used steel grades include carbon steel, stainless steel, and alloy steel. The choice of material depends on factors such as strength requirements, corrosion resistance, and the final application of the fabricated product.

3. Cutting:

Once the design is finalized and the materials selected, the steel goes through the cutting process. Various cutting methods, such as sawing, shearing, or laser cutting, are employed based on the thickness and type of steel. This step is crucial for shaping the steel into the desired components before the subsequent processes take place.

4. Shaping and Forming

After cutting, the steel components undergo shaping and forming processes to achieve the intended design. Techniques like bending, rolling, and stamping are employed to give the steel its required shape. Precision is key in this stage, as any deviation from the design can compromise the structural integrity of the final product.

5. Welding and Assembly

Welding is a fundamental aspect of steel fabrication, where individual steel components are fused to create a unified structure. Skilled welders use various welding techniques, such as arc welding, MIG (Metal Inert Gas) welding, or TIG (Tungsten Inert Gas) welding, depending on the project’s requirements. The assembly phase involves combining all the fabricated components into the final structure, adhering to the specifications outlined in the design.

What are its Applications?

It is a versatile process with applications across numerous industries. Its adaptability, strength, and durability make it an ideal choice for a wide range of projects.

1. Construction Industry

Steel fabrication is a cornerstone of the construction industry, providing the framework for buildings, bridges, and other infrastructure. From structural beams and columns to intricate architectural elements, steel plays a pivotal role in ensuring the stability and longevity of modern structures.

2. Manufacturing

The manufacturing sector relies on the fabrication of steel for the production of machinery, equipment, and industrial components. The precision and strength of fabricated steel make it a preferred material for manufacturing applications, ensuring the reliability of the finished products.

3. Automotive

In the automotive industry, the fabrication of steel is essential for crafting vehicle components that require strength, durability, and precision. From chassis and frames to engine components, steel’s versatility makes it a preferred material for ensuring the safety and performance of automobiles.

4. Aerospace

Aerospace engineering demands materials that can withstand extreme conditions, and steel fabrication meets this requirement. Aircraft components, such as wings, fuselage structures, and landing gear, often undergo meticulous steel fabrication processes to meet the stringent safety and performance standards of the aviation industry.

5. Energy Sector

In the energy sector, the fabrication of steel is crucial for constructing power plants, pipelines, and offshore structures. The ability of steel to withstand environmental challenges, such as extreme temperatures and corrosive conditions, makes it an indispensable material for energy infrastructure projects.

Innovations in the Fabrication of Steel

As technology continues to advance, innovations in steel fabrication are driving the industry toward greater efficiency, sustainability, and cost-effectiveness.

1. Advanced Robotics

The integration of advanced robotics into fabrication processes has revolutionized efficiency and precision. Robots can perform repetitive tasks with unparalleled accuracy, reducing the margin of error and enhancing overall productivity. This not only accelerates the fabrication process but also ensures consistency in the quality of the finished products.

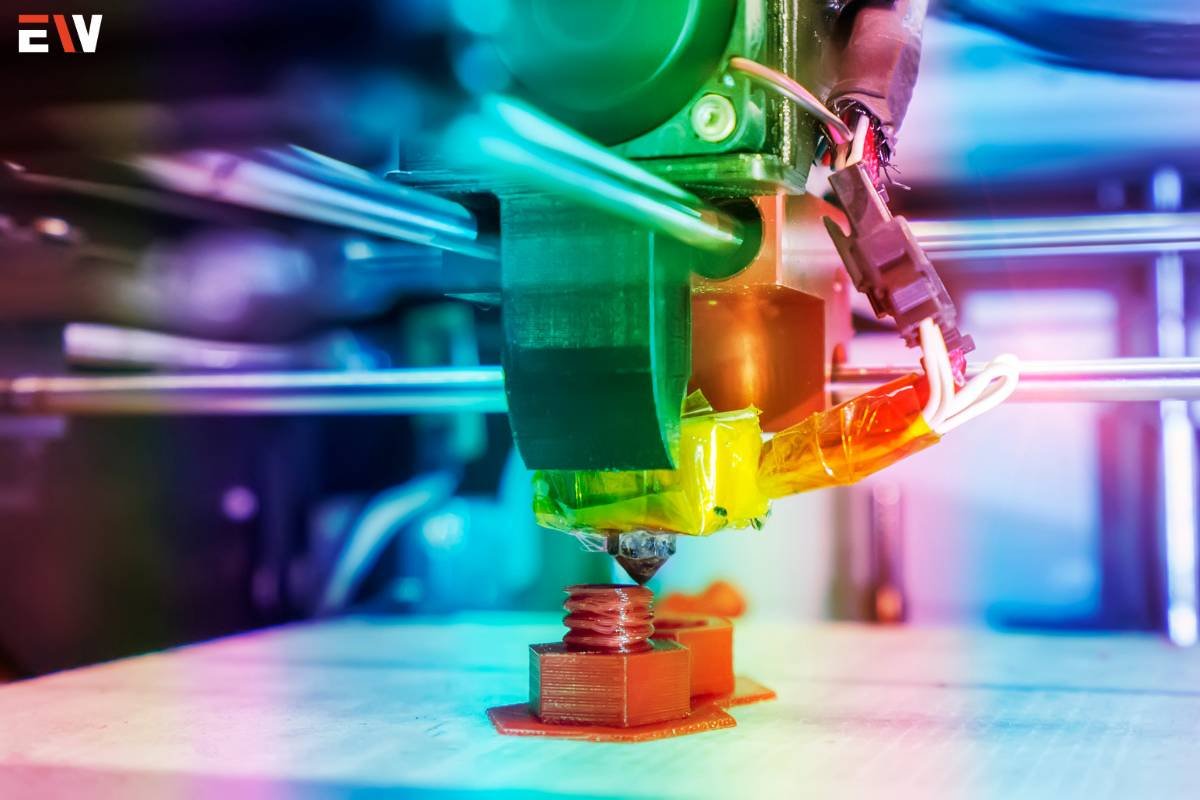

2. 3D Printing

Additive manufacturing, or 3D printing, has made significant inroads into steel fabrication. This innovative technique allows for the layer-by-layer construction of complex steel structures, offering unprecedented design flexibility and resource efficiency. While 3D printing in steel fabrication is still in its early stages, it holds tremendous potential for revolutionizing the industry in terms of speed and customization.

3. Sustainable Practices

The steel industry is increasingly adopting sustainable practices to minimize its environmental impact. Recycling of steel is a common practice, with scrap steel being melted down and reused in the fabrication process. Additionally, efforts to reduce energy consumption and minimize waste are driving the industry toward a more environmentally friendly future.

Conclusion

Steel fabrication is both an art and a science, a process that transforms raw steel into the backbone of modern infrastructure. From towering skyscrapers to intricate machinery, the fabrication of steel shapes the world around us.

As technology advances, the industry evolves, embracing innovations that enhance efficiency, sustainability, and precision. With its versatility and strength, steel remains an indispensable force, continually pushing the boundaries of what is possible in construction, manufacturing, and beyond.