In the ever-evolving landscape of product development and innovation, rapid prototyping has emerged as a game-changing methodology. This comprehensive guide delves into the intricacies of fast prototyping, exploring its definition, methodologies, applications, benefits, and how it is reshaping the way products are conceptualized, designed, and brought to market.

Understanding Rapid Prototyping

1. Defining Rapid Prototyping:

It is a methodology that involves creating tangible models or prototypes quickly to visualize, test, and iterate on design ideas. It provides a dynamic and iterative approach to product development, allowing teams to validate concepts and make informed decisions early in the design process.

2. Prototyping vs. Traditional Methods

Unlike traditional product development, which may involve lengthy design cycles and extensive documentation, rapid prototyping emphasizes swift iterations and real-time feedback. It accelerates the time from concept to prototype, fostering agility and adaptability in the development process.

3. Key Components:

- Conceptualization: Generating and refining design concepts quickly.

- Creation of Prototypes: Building physical or digital prototypes for testing and validation.

- Iterative Testing: Collecting feedback and making rapid adjustments to improve the prototype.

- Collaboration: Involving cross-functional teams in the prototyping process for diverse perspectives.

Methods and Techniques

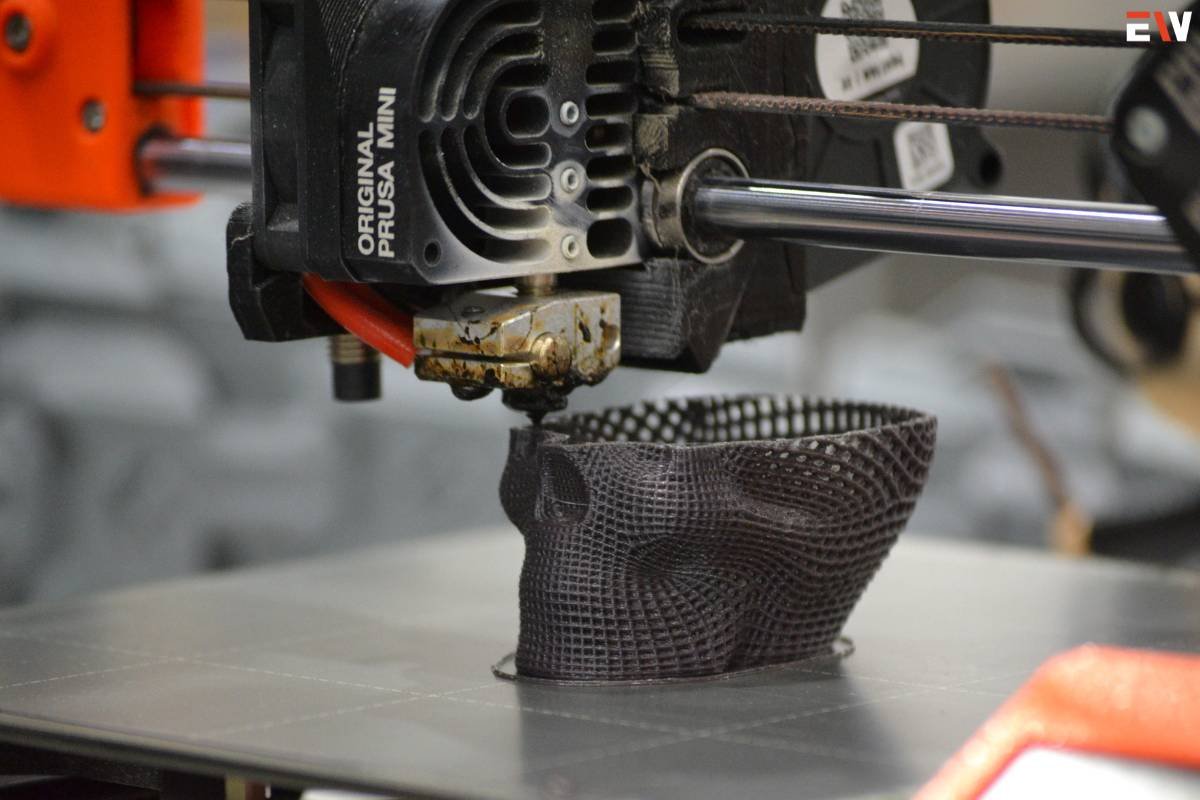

1. 3D Printing

Utilizing additive manufacturing techniques to create physical prototypes layer by layer. 3D printing allows for the rapid production of complex and detailed prototypes, facilitating iterative testing.

2. CNC Machining

Computer Numerical Control (CNC) machining involves subtractive manufacturing, carving out prototypes from raw materials. While not as rapid as 3D printing, CNC machining is suitable for high-precision prototypes.

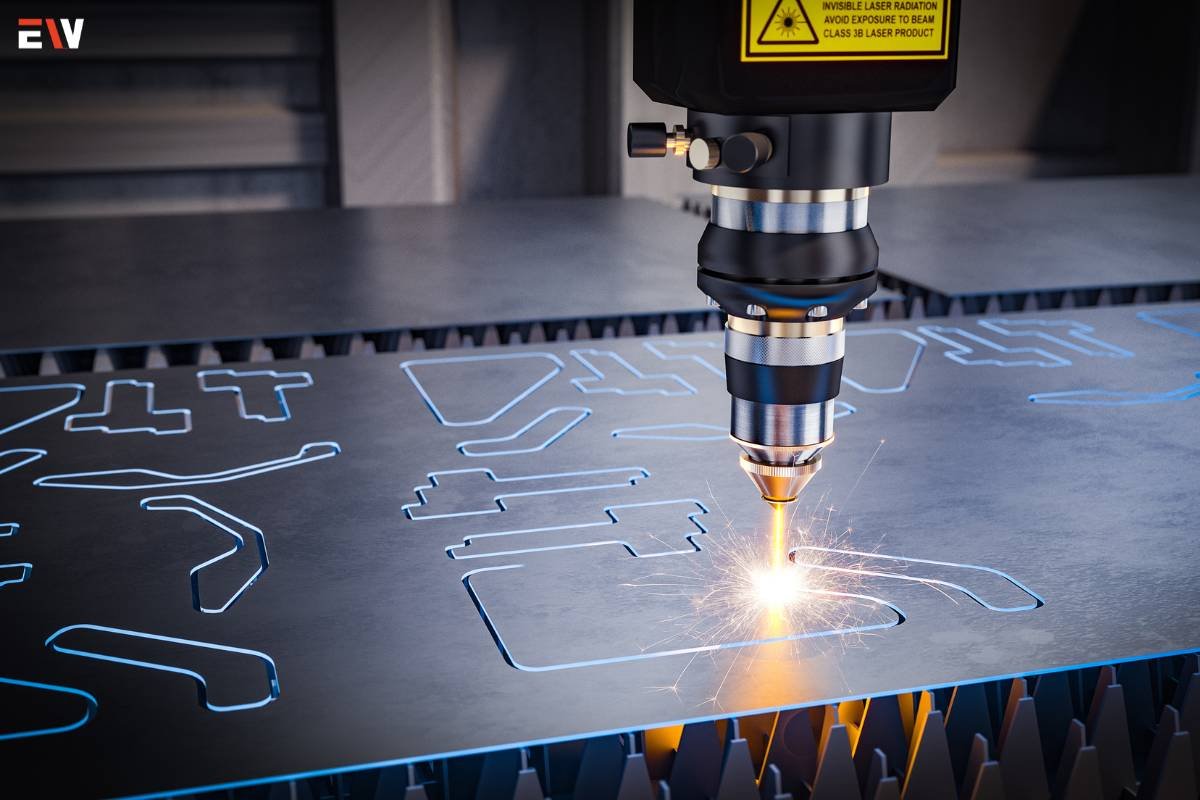

3. Laser Cutting

Laser cutting uses focused laser beams to cut through materials, creating detailed and intricate prototypes. It is a rapid and cost-effective method for producing flat prototypes.

4. Virtual Prototyping

Employing computer-aided design (CAD) software to create digital prototypes. Virtual prototyping allows for quick adjustments and simulations before physical prototypes are produced.

5. Rapid Injection Molding

Rapid injection molding replicates the final product using molds, allowing for the production of small batches of prototypes with properties similar to the end product.

Applications of Rapid Prototyping

1. Product Design and Development

Fast prototyping accelerates the product design cycle, enabling designers to visualize and test concepts quickly. It is particularly valuable in industries such as consumer electronics, automotive, and industrial design.

2. Medical Prototyping

In the medical field, fast prototyping is used for creating patient-specific models, surgical guides, and prototypes of medical devices. This methodology enhances precision and customization in healthcare solutions.

3. Aerospace Engineering

Aerospace engineers use fast prototyping to create scale models of aircraft components, test aerodynamics, and iterate on designs. This accelerates the development of new aerospace technologies.

4. Consumer Goods and Packaging

fast prototyping is integral in the consumer goods industry for designing and testing packaging solutions. It allows for quick adjustments to enhance the functionality and appeal of products.

5. Architectural Prototyping

Architects utilize rapid prototyping to create scale models of buildings, allowing clients and stakeholders to visualize designs in three dimensions. This facilitates collaborative decision-making in architectural projects.

Benefits of Rapid Prototyping

1. Reduced Time to Market

fast prototyping significantly shortens the time required to move from the conceptualization phase to the final product. This accelerated timeline is crucial in highly competitive markets.

2. Cost Savings

By identifying and addressing design flaws early in the process, rapid prototyping minimizes the costs associated with rework and modifications during later stages of development.

3. Enhanced Collaboration

fast prototyping encourages cross-functional collaboration. Designers, engineers, and stakeholders can actively participate in the prototyping process, contributing diverse perspectives and insights.

4. Iterative Testing and Improvement

The iterative nature of rapid prototyping allows for continuous testing and improvement. Teams can gather feedback, make adjustments, and refine prototypes rapidly, resulting in a more polished and user-centric end product.

5. Visualizing Complex Designs

Physical or digital prototypes provide a tangible representation of complex designs. This visualization aids in communicating ideas effectively within the team and to external stakeholders.

6. Risk Mitigation

Fast prototyping enables the identification of potential risks and challenges early in the development process. This proactive approach mitigates risks before substantial resources are invested in full-scale production.

7. Customization and Personalization

Industries such as healthcare and consumer goods benefit from the customization capabilities of fast prototyping. It allows for the creation of personalized solutions tailored to specific user needs.

8. Innovation and Creativity

Rapid prototyping fosters a culture of innovation and creativity within teams. The ability to experiment with ideas quickly encourages bold exploration and pushes the boundaries of traditional design thinking.

Challenges and Considerations

1. Material Limitations

The availability of suitable materials for certain prototyping methods may be limited. Choosing the right material is crucial to ensuring that prototypes accurately represent the final product.

2. Cost of Equipment

Acquiring and maintaining equipment for certain fast prototyping methods, such as 3D printing or CNC machining, can incur significant costs. Organizations need to weigh the benefits against the initial investment.

3. Scale-Up Challenges

While rapid prototyping is efficient for small-scale production and testing, challenges may arise when transitioning to large-scale manufacturing. The scalability of the chosen prototyping method should be considered.

4. Skill Requirements

Operating advanced prototyping equipment and software may require specialized skills. Organizations should invest in training or hire skilled professionals to maximize the benefits of fast prototyping.

5. Security and Intellectual Property Concerns

Sharing detailed prototypes, especially in digital form, raises concerns about intellectual property and security. Organizations must implement measures to protect sensitive information during the prototyping process.

6. Integration with Traditional Processes

Integrating fast prototyping with existing traditional product development processes may pose challenges. Seamless coordination between rapid prototyping and traditional methods is essential for a cohesive development workflow.

Future Trends

1. Advancements in Materials

Ongoing research and development in materials science will lead to the availability of new and improved materials for fast prototyping. This will enhance the properties and applications of prototypes.

2. Hybrid Prototyping Approaches

The integration of multiple fast prototyping methods in a hybrid approach will become more prevalent. Combining techniques such as 3D printing, CNC machining, and virtual prototyping will offer a holistic and versatile solution.

3. AI and Generative Design

Artificial intelligence (AI) and generative design algorithms will play a significant role in shaping and optimizing prototypes. These technologies will contribute to more efficient and innovative design processes.

4. Decentralized Prototyping Facilities

The rise of decentralized and on-demand prototyping facilities will provide greater accessibility to organizations. This trend aligns with the growing need for flexible and localized production capabilities.

5. Integration with Industry 4.0

Fast prototyping will increasingly integrate with Industry 4.0 technologies, such as the Internet of Things (IoT) and data analytics. This convergence will create smarter, data-driven, and more responsive prototyping processes.

Conclusion

Rapid prototyping stands at the forefront of modern innovation, revolutionizing the way products are conceived, designed, and realized. Its impact spans across industries, from accelerating time to market to fostering a culture of creativity and collaboration.