Electro discharge machining (EDM) is said to be the backrooms of high-tech manufacturing plants, but in reality, its influence touches everyday life far more often than you might imagine. EDM plays an essential role, from detailed automotive components to the precise molds shaping our smartphone casings in today’s modern manufacturing processes. In this article, we will explore what electro-discharge machining is and why it acts as a game-changer within the world of precision engineering.

What is Electro Discharge Machining?

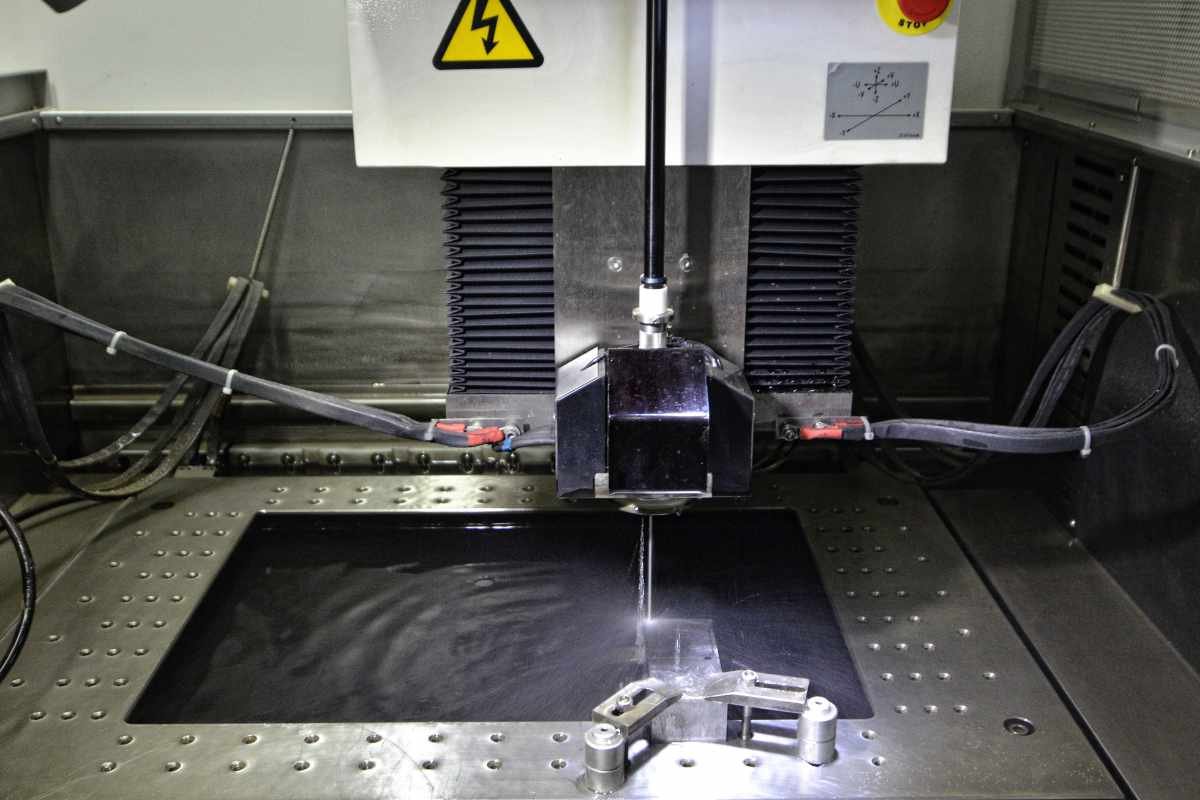

EDM is a non-conventional machining process wherein electrical discharges (sparks) are used to perform a desired shape on conductive materials. Other than the mechanical force of a conventional machine tool, the energy of EDM’s electrical discharges is converted to minute, very rapid heat bursts that vaporize small pieces of metal.

EDM is very effective for hard materials, such as hardened steel, titanium, and superalloys, which are difficult to cut by the conventional machining process. It involves a dielectric typically either deionized water or which cools the sparks, removes the swarf, and controls the path of the sparks, hence carrying out remarkably precise and smooth finishes.

How Electro Discharge Machining Works?

The process of EDM starts with two electrodes: one serving as the workpiece and the other as the tool, commonly known as the electrode or “die.” These electrodes are immersed in a dielectric fluid and positioned close to each other, ensuring they do not make contact. When a voltage is applied, an electric field forms between them. As the electrodes draw closer, the intensity of the electric field increases until it reaches a threshold where a spark jumps across the gap, melting and vaporizing a tiny part of the workpiece.

This process repeats thousands of times per second, with each spark removing a small amount of material and gradually sculpting the desired shape into the workpiece. The precision of electro-discharge machining allows the creation of complex shapes and fine details, making it invaluable in industries where accuracy is paramount, such as aerospace, medical devices, and mold-making.

Types of Electro Discharge Machining

Depending on the shape of the electrode and the process setup, we can achieve many different shapes and degrees of accuracy from raw material. We can classify the EDM processes into three distinct types.

| Sinking EDM (Die- Sinking) | Wire EDM Machining | Hole Drilling EDM |

| An electrode is shaped to match the negative of the desired cavity.Ideal for creating molds and dies with complex, intricate shapes | Uses a thin wire as a cutting tool. This technique is perfect for cutting contours and fine features such as the gears found in luxury watches. | Specializes in drilling precise holes, particularly in hard materials. EDM allows for high-speed drilling of small, deep holes with extreme accuracy. |

Applications of Electro-Discharge Machining

The applications of Electro Discharge Machining are as varied as they are fascinating. Here are some applications of EDM:

- Aerospace Industry: Used for manufacturing complex components like turbine blades and cooling holes with high precision for performance and safety standards.

- Automotive Industry: Applied to molds for casting high-precision engine components, enhancing accuracy, tolerances, and finishes.

- Medical Devices: Utilized in producing surgical instruments and implants, meeting strict accuracy and biocompatibility standards; for example, precise holes in stents for drug release.

The Future of Electro Discharge Machining

The advancement in technology has led to an increase in potential in electro-discharge machining. Automation, AI, and Machine Learning are developing EDM into processes that will be faster, wiser, and more efficient. Electro discharge machining machines networked on the factory floor, sharing data and optimizing their operations in real-time. This level of integration could well revolutionize manufacturing, pushing costs down while driving up new heights in precision and efficiency.

The continuous development of new electrode materials and dielectric fluids further reinforces ongoing efforts to speed up and fine-tune the EDM processes. Researchers are working on new ways to reduce electrode wear and extend the life of dielectric fluids; their work may provide even more economical and environmentally friendly manufacturing methods.

Advantages of EDM:

Electro Discharge Machining (EDM) is highly valued for its precision and ability to machine complex shapes in hard materials like tool steel and titanium. Because there is no direct contact between the tool and the workpiece, mechanical stress is minimal, allowing for intricate features and smooth finishes without burrs. EDM is a versatile discipline whose applications range from aerospace, and the automotive industries, to medical device manufacturing.

Disadvantages of EDM:

EDM has certain limitations, though. The main reason is that it is a slow process compared to conventional methods of machining. The energy consumption is extremely high since only electrically conductive materials can be treated and the application is limited to metals only. The wear of the electrode will affect precision and may increase the cost of production. High temperatures are generated, which might cause thermal damage to the workpiece. The dielectric fluids used can be hazardous to health and safety. Any contact with them is done carefully. Therefore, apart from these drawbacks of EDM, it remains a go-to in applications that require high precision and complexity.

Conclusion

Electro discharge machining is much more than a means to cut metal; it is a doorway to precision and innovation in manufacturing. Its ability to work with hard materials, produce intricate details, and maintain high accuracy has cemented its place as a cornerstone of modern production techniques. Nor, for that matter, is it all that difficult to imagine that as industries continue to evolve and demand even greater precision, EDM’s spark will light the way forward the components of tomorrow with today’s precision.